A Finnish solution in North American waters

As Aker Arctic Technology celebrates its 20th anniversary, a new chapter in icebreaker design and construction has begun with the signing of the ICE (Icebreaker Collaboration Effort) Pact. A trilateral partnership between the United States, Canada, and Finland, the ICE Pact coordinates the member countries to combine resources and technology to collaborate on the construction of new, modern icebreakers.

Aker Arctic Technology and its predecessors have always been at the forefront of icebreaker design and is now supporting the ICE Pact partners in icebreaking technology. From the design and engineering support for the United States’ medium icebreaker, USCGC Healy (WAGB-20), based on the Finnish icebreaker Otso, to the recent developments in the design and engineering support for Seaspan’s Polar Icebreaker and MPVs for the Canadian Coast Guard, more is to come under the ICE Pact. Aker Arctic has been providing vital icebreaker solutions for North American waters.

Background of USCGC Mackinaw (WLBB-30)

One of the unique challenges in designing and engineering icebreakers for North American waters is conducting icebreaking operations in the Great Lakes. With a fundamentally different winter navigation system than that of the Baltic Sea, heavy ridging, and freshwater ice that is harder than sea ice, collaboration with our North American partners was vital in developing successful solutions suitable for North American operators.

Delivered in 2006, USCGC Mackinaw (WLBB-30) is an excellent example of this collaboration, in which Aker Arctic Technology and its predecessor worked closely with the USCG and the American shipbuilding industry on the design and building of the heavy Great Lakes icebreaker.

In the late 1990s, the only U.S. heavy icebreaking resource in the Great Lakes, CGC Mackinaw (WAGB-83), had been in operation for over 50 years. A state-of-the-art icebreaker at the time of her delivery, she had far exceeded her service life, with multiple decommissioning plans that never came to fruition. As she became too expensive to maintain and operate, the plan was to go ahead with a replacement icebreaker/buoy tender.

The initial Mackinaw design

Aker Arctic Technology’s predecessor, Kvaerner Masa-Yards Arctic Technology Centre (MARC), assisted the USCG in developing the preliminary concept for the vessel to replace CGC Mackinaw (WAGB-83). The naval architects at the USCG were investigating the feasibility of an icebreaker/buoy tender solution.

The USCG’s initial hull form to replace CGC Mackinaw (WAGB-83) was a relatively traditional icebreaking hull form with a small stem angle and wide frame angles in both the bow and stern, and twin shaftline propellers in the stern. Designed to be a small, nimble icebreaker with good shoulders and sloped sides to allow for good manoeuvrability, the initial vessel was representative of late 20th-century icebreaking technology, akin to other icebreakers of the 1980s, such as the twin-shafted USCGC Healy (WAGB-20).

Nevertheless, the early Mackinaw hull form that was developed was still a relatively heavy icebreaking hull form, facing some disadvantages in open water —namely, slamming and rolling in heavy seas. Its nimble size featured sharp transition angles that risked flow separation at higher open-water speeds. The USCG had utilized new modern numerical tools in the development of the hull form; however, further improvements were still possible in the design of the vessel given the many innovations since the delivery USCGC Healy (WAGB-20).

A testing program to determine the propulsion system configuration

At the time of planning and design for the replacement of CGC Mackinaw (WAGB-83), the capabilities of azimuthing propulsion in ice had become a proven concept. Various built ships, such as Uikku, Mastera, and Tempera, demonstrated the unique capabilities azimuthing propulsion provided in both manoeuvring and double-acting icebreaking. Compared to traditional propulsion systems, azimuthing propulsion significantly enhanced ship performance in icy waters.

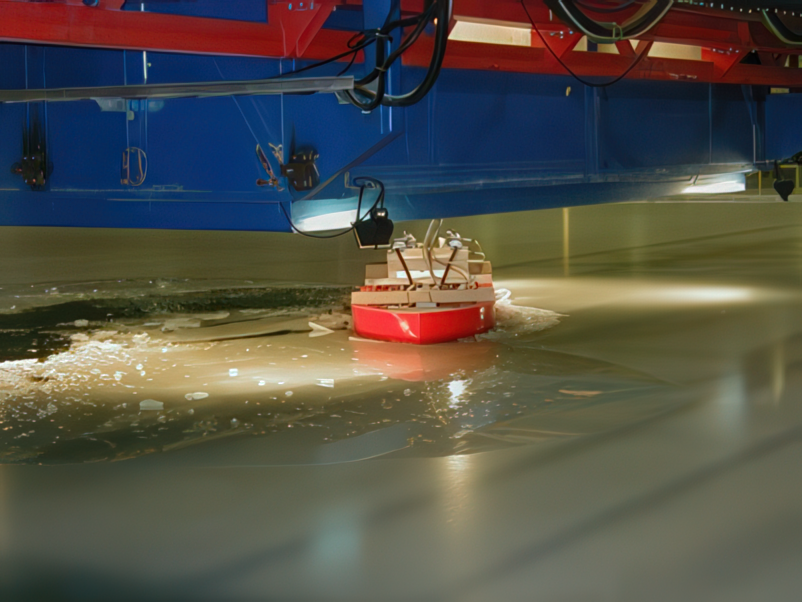

A testing program was conducted to demonstrate the effectiveness and potential of this advanced technology. A series of tests was performed with the baseline hull form, comparing the performance of the vessel in ice with twin shaftline controllable pitch propellers (CPP) versus azimuthing propulsion in the stern.

| Test Description | Azipod | CPP |

| Icebreaking, ahead (1.0 m/s) | 0.95 m | 0.92 m |

| Icebreaking, astern (0.5 m/s) | 0.85 m | 0.75 m |

| Level ice (0.81 m) ahead | 2.1 m/s | 1.6 m/s |

| Level ice (0.81 m) astern | 0.7 m/s | 0.2 m/s |

| Brash ice (2.44 m), ahead | 3.2 m/s | 3.2 m/s |

| Brash ice (2.44 m), astern | 3.4 m/s | 1.35 m/s |

| Cutting free beset vessel, ahead | 9 min. | > 30 min |

| Cutting free beset vessel, astern | 10 min. | 22 min |

| Star manoeuvre | 4 min. | > 21 min |

| Breaking out track, ahead | 130 m | > 500 m |

| Breaking out track, astern | 70-90 m | > 220 m |

| Turning circle | 152 m | > 743 m |

Model test results comparing the and shaftline version of an early variant of USCGC Mackinaw (WLBB-30)

The vessel’s performance with azimuthing propulsion excelled in almost every category. The azimuthing propulsion variant was able to penetrate icy waters at the same speed, or even faster than the CPP variant. Despite ice hitting and getting lodged/ jammed on the struts of the azimuthing propulsion units, the azimuthing thruster variant was still outperforming the CPP variant in astern operations in ice. Manoeuvring times and distances were 2 to 5 times shorter than the CPP variant. Azimuthing propulsion ultimately proved to be the best solution for the USCG to move forward with.

Further validation to meet performance requirements

Afterward, the USCG worked on their design behind the scenes and arrived at a point design that was released for tender in 2000. This tender sought for a suitable shipyard to build the ship. Initially collaborating with Avondale Industries, based on previous cooperation in developing USCGC Healy (WAGB-20), and then with Halter. However, the winning bid was ultimately awarded to Marinette Marine.

By winning the bid, Marinette Marine became responsible for the performance requirements of the vessel. However, they needed further validation to secure the final shipbuilding contract. Marinette Marine turned to Finland, whose expertise in both designing and building icebreakers, as well as extensive experience in Double Acting Ships, was needed to ensure success.

Retired veteran Aker Arctic naval architect Matti Arpiainen shares that even though the original design work was mostly carried out in-house by the USCG, and the production engineering was to be done at Marinette Marine, Finnish experts were contracted to perform design checks, ice strengthening checks, and a hull form study.

Matching the hull with the propulsion configuration

The original baseline hull form was still a traditional cruiser stern, optimized for twin shaftline propellers. The first set of model tests resulted only in changing to azimuthing propulsion, without modifying the stern to match it. This, however, led to poor interaction between ice and the thruster struts.

There was still potential for improving the ship’s capabilities by properly adjusting the hull to match the propulsion system. A hull form study was completed to further optimize the hull by assessing four variants of the vessel. Of these, two were selected for model testing: the baseline hull and one with the relatively novel design of the double-wedged stern that was only previously implemented in shallow-draft vessels (also highlighted in our FESCO Sakhalin article).

The flexural strength of the ice used in the model tests was set to 110 psi to account for the hard ice of the Great Lakes, which is one and a half times stronger than sea ice. In model tests, the double-wedged variant proved to perform equal to, or better, in all areas of testing, and showed superior backing performance in ice. Where the point design had the issue of ice becoming lodged/jammed between the pods and ice hitting the thruster struts, the double-wedged stern was able to break the ice before it reached the thruster struts, protecting them from ice and further optimizing the flow of ice to minimize resistance.

Furthermore, while the point design would have become trapped when going astern, the double-wedged stern variant was able to cruise through at over 4 knots. The double-wedged stern did require 5% more power in open water for the same speed but had no negative impact on the vessel’s open-water seakeeping and manoeuvring capabilities. Overall, the advantages of the double-wedged stern with azimuthing thrusters stood out as a critical solution for the new Mackinaw, making her a capable and agile heavy Great Lakes icebreaker.

Further improvements for the state-of-the-art icebreaker of its time

Although the vessel’s bow lines were well optimized for level icebreaking due to its hull angles, it also meant the vessel would encounter difficulty in pressure ridges, especially due to the small size of the vessel. One method to address this is by adding a forefoot or ice knife to prevent the vessel from riding up onto ridges. In consideration of this risk, an ice knife was added to the point design.

However, the design of an ice knife is critical as the shape has to prevent excessive resistance in both open water and in ice, not to mention appropriate ice strengthening. A poorly designed ice knife can introduce additional drag in open water and result in ice getting lodged in front of it during icebreaking, adding additional resistance to push the ice. The initial ice knife exhibited vortex shedding, increasing resistance by 6%, but was refined through modifications made during the hull form study.

A paint investigation was also done to establish a suitable paint for USCGC Mackinaw (WLBB-30). Alternative paint options were tested in the ice tank to determine a suitable abrasion-resistant, low-friction paint suitable for USCG operations. Poor paint on a ship hull considerably increases the friction component in ice resistance, as ice and snow drag alongside a rough hull.

Exceptional capabilities proven in ice trials

USCGC Mackinaw (WLBB-30) was delivered in 2005 and underwent ice trials in 2007. Aker Arctic participated in the ice trials, observing firsthand the vessel’s exceptional capabilities in ice. Gliding through and manoeuvring around ice with great agility, the capabilities of the vessel were further improved through proper operational methods.

Under the guidance of a Finnish icebreaker captain USCG operators learned to operate their first modern double-acting icebreaker. By utilizing flushing and wake effects from the azimuthing thrusters to add further utility, the USCG was able to receive hands-on directions on how to operate a modern icebreaker and take full advantage of its potential.

With key input and invaluable collaboration, USCGC Mackinaw (WLBB-30) became a state-of-the-art icebreaker for its time, following the legacy of CGC Mackinaw (WAGB-83). As USCGC Mackinaw (WLBB-30) approaches 20 years of service, innovations in icebreaking technology continue to advance, which we will cover in upcoming articles in this series. Technology transfer has been very successful between Finland and North America, and in the new age of icebreaking under the ICE Pact, an opportunity opens for further collaboration to design and build new capable icebreakers better and faster than ever before.

Text: Aaron Tam