Antarctic science: The French polar logistics vessel L’Astrolabe

For two decades, Aker Arctic has helped nations and research institutes reach the farthest corners of the Earth – from Arctic ice to Antarctic seas – through purpose-built vessels designed to endure nature’s toughest tests. As part of our 20th-anniversary series, we look back at the creation of the polar logistics vessel L’Astrolabe – a ship born of urgency, expertise, and international collaboration.

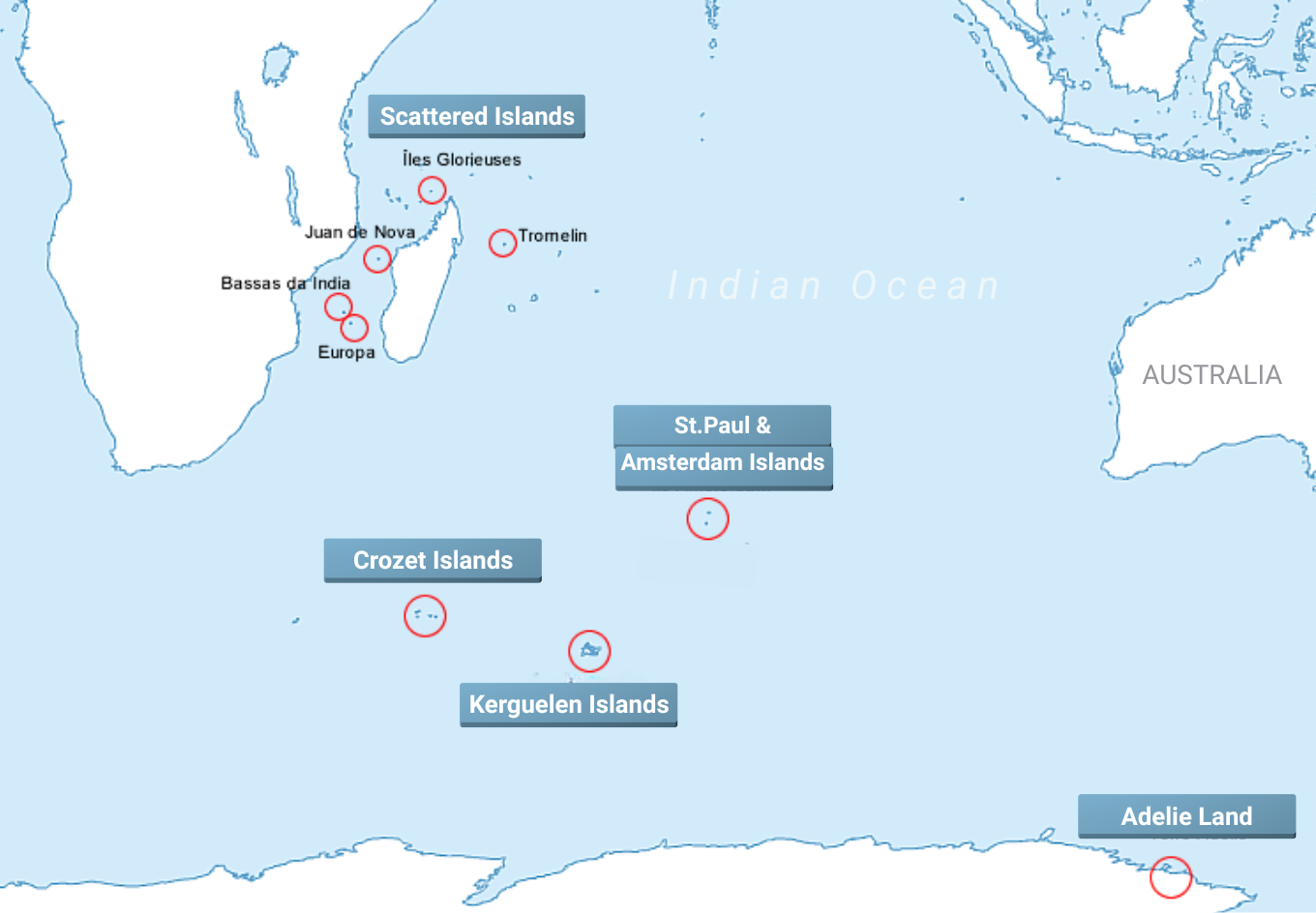

In January 2015, Aker Arctic was approached by the French shipyard Chantiers Piriou. They were seeking an ice specialist who could turn an initial polar-vessel concept into a state-of-the-art ship capable of withstanding the frozen seas of Antarctica. The vessel was being commissioned for three French institutions: Les Terres Australes et Antarctiques Françaises (TAAF), the Institut Polaire Français Paul-Émile Victor (IPEV), and the French Navy.

The project’s goal was ambitious: to build a ship that would replace both the 1966-built patrol vessel L’Albatros and the 1986-built polar logistics vessel L’Astrolabe. The new ship would resupply the French Antarctic base at Dumont D’Urville during the southern summer, and, when the season closed, she would patrol the tropical waters around Réunion Island in the Indian Ocean.

Decades of polar experience

The initial concept for the vessel was prepared by the French engineering company Marine Assistance. Given Aker Arctic’s strong background in supporting Antarctic programmes, the research institutes and the French Navy were eager to ensure our involvement in the subsequent design phases. The project needed the insight of people who truly knew ice.

“We have designed numerous ships for the Arctic and Antarctica, and conducted several research expeditions to the polar regions since the 1960s, gaining deep experience and respect for the forces at play in such environments,” says Chief Designer Lars Lönnberg.

Antarctica is the most isolated continent on Earth, with no supporting infrastructure anywhere nearby. Icebreakers operating here must be entirely self-sufficient for months at a time, carrying everything from fuel and provisions to spare parts and equipment for emergency repairs. Strict environmental protocols under the Antarctic Treaty add another layer of complexity to these demanding missions.

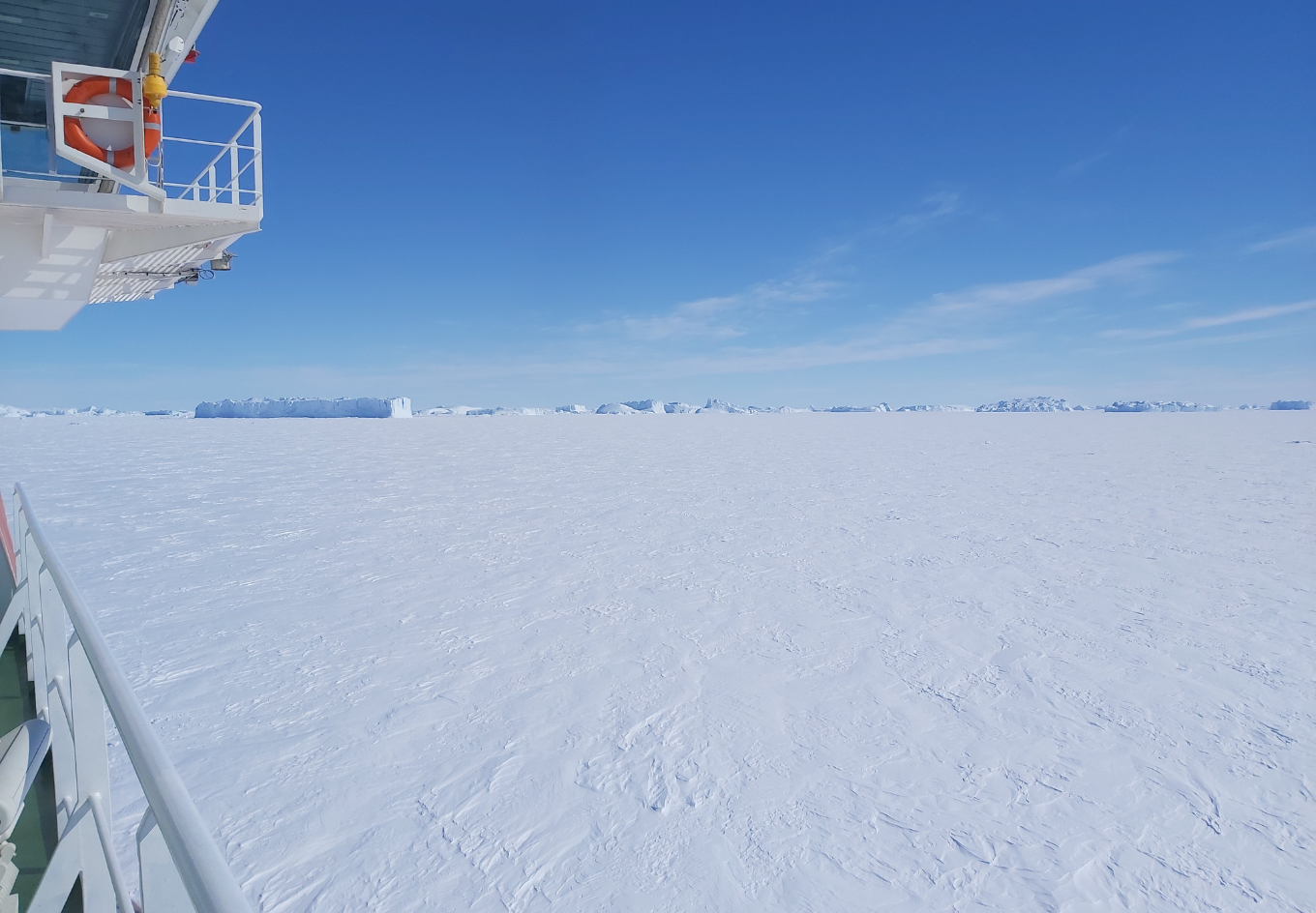

Sea ice in the Southern Ocean forms under colder, more stable conditions than in the Arctic. Ice conditions there can often contain multi-year ice and/or large pressure ridges, as well as land-based ice such as bergy bits, growlers, and icebergs from Antarctica that challenge even the most powerful hulls and propulsion systems. Acknowledging and managing such risks in the design of an Antarctic icebreaker is essential.

Icebreakers must also withstand towering swells, fierce blizzards, and rapidly changing weather, often in sub-zero temperatures that test machinery, electronics, and human endurance. On top of that, research and resupply missions involve long open-water transits, requiring ships to perform efficiently both in ice and open seas – a balance that demands solid expertise to achieve.

Two years from design to delivery

Aker Arctic’s task was to ensure that the vessel could operate safely and reliably in such demanding conditions. This included performing the basic design, ensuring that all ice-class requirements were met, verifying the vessel’s design and icebreaking performance through model tests at our ice basin in Finland, and providing technical support to the shipyard during construction.

By June 2015, the contract was signed, with a demanding two-year timeline to design, test, and deliver a ship capable of challenging the polar regions. Marine Assistance would remain as the owners’ advisor, but the design and technical responsibilities were passed on to Aker Arctic and Piriou Shipyard.

Redesigning for the ice

When our engineers first reviewed the initial concept, they quickly realised the design would need major revisions to meet both the Polar Code and Special Purpose Ship (SPS) Code. These rules mandate that even if a ship’s hull is damaged, it must remain stable and afloat with limited heel, and be safe for everyone aboard.

Working within strict dimensional limits – no extra length or beam – our designers reshaped the hull, rearranged internal spaces, reinforced the steel structure, and developed the design further to meet the classification society Bureau Veritas’ ice-class requirements.

“We were not allowed to change the vessel’s size, which made things challenging,” explains Lönnberg. “In our own vessel concepts, we design according to the customers’ operational and functional requirements, as well as international regulations from day one. Adjusting later often leads to complex, costly solutions, which can complicate construction.”

For example, in L’Astrolabe, certain steel reinforcements had to be added, which made construction more complex, and the skeg had to be redesigned for buildability.

Putting design to the test

Two months later, the design faced its first trial: a series of ice model tests. In the chilled basin in Finland, a scale model of L’Astrolabe pushed through layers of meticulously prepared ice. The results confirmed her capabilities: breaking 80 cm of level ice at two knots, operating in areas with second-year ice, and navigating through coastal ice up to one metre thick at full concentration (10/10).

The team then turned to seakeeping tests to see how the vessel would behave in the roaring waves of the Southern Ocean. Managing icebreaking capabilities alongside good open-water performance requires careful optimisation to achieve the right balance. The tests demonstrated L’Astrolabe’s capability to handle both extremes.

Her diesel-mechanical propulsion system was chosen for efficiency during long open-water transits. In ice operations, however, a diesel-electric power transmission system is usually favoured, and, when combined with azimuthing propulsion, can greatly improve a vessel’s operability in ice. Therefore, additional resistance and propulsion tests were performed to fully assess the vessel’s performance under all conditions.

Multiple roles in a compact design

By January 2016, design work and model testing were complete. Despite her compact size, L’Astrolabe was designed to be a true multi-mission vessel.

She can carry large quantities of supplies, containers, heavy machinery, pallets, liquid drums, and personnel, all vital for the remote Dumont D’Urville base. Her aft deck doubles as a working platform with an A-frame for lowering oceanographic equipment, while a helicopter landing area adds further versatility for Antarctic operations.

Below deck, her four Wärtsilä 8L20 main engines deliver 6.4 MW of propulsion power through two shaftlines. For each shaftline, a pair of engines is connected to a reduction gear, which can each be coupled to a 500 kW power take-off generator, primarily used for the bow thrusters. Two auxiliary generator sets provide electricity for the ship. All engines meet IMO Tier III regulations.

The controllable pitch propellers (CPP) on both shaftlines allow the ship to change speed without reversing engine rotation. This setup provides fast response times – a critical feature for when the ship operates in tough icy conditions.

High above the deck, an aloft conning station equipped with advanced surveillance systems supports both research and patrol duties. When needed, it can serve as a defence platform, with automatic weapon systems integrated into its design.

“We succeeded in fitting all functions into this compact design, although it proved to be quite a puzzle,” Lönnberg highlights. “Certain areas, such as the gym, had to make way for an additional machinery space, and the helicopter hangar was converted into a container space on the deck. Accommodating cabins for 60 people was also quite an achievement for a vessel of this size.”

Support throughout construction

The construction of L’Astrolabe was itself a journey. Her steel hull was first built at CRIST in Gdynia, Poland, before being towed across Europe to Concarneau on France’s Atlantic coast, for outfitting and final completion at Piriou Shipyard.

Aker Arctic’s contract with Piriou Shipyard also included technical support during construction, as the shipyard had no experience of building ice-class vessels. Our experts made regular trips to both Poland and France over the entire construction period to check hull reinforcements, provide guidance, and verify that all ice-navigation features and winterisation requirements were implemented correctly – crucial details essential for safety and performance in Antarctic conditions.

Successful sea trials in Bretagne

Inclining tests were performed in May 2017 to verify the vessel’s lightweight and centre of gravity, followed by open-water tests a month later. These trials confirmed the ship’s performance in speed, endurance, noise, vibration, turning, and manoeuvrability.

Hydrodynamic engineer Artur Nerman from Aker Arctic, who joined the tests, recalls:

“We departed from the port of Concarneau for sea trials in the morning and returned late at night on 30 June 2017. After many other tests, including system checks and adjustments, the actual speed trials were carried out at the end of the day. By that time, the wind had increased and affected the ability to obtain stable measurement results. The first speed point was successful, but the second had to be repeated a few weeks later in calmer seas.”

Ready for the ice

In September 2017, L’Astrolabe was delivered exactly on schedule. Her first assignment took her to Réunion for patrol duties, followed by a voyage to Tasmania for cargo loading. Then, in early 2018, she embarked on her maiden crossing to Antarctica.

Since then, she has completed up to five round trips per season between Hobart and the Dumont d’Urville station in Antarctica, braving the harsh Antarctic seas from November to March.

According to Piriou Shipyard, after the delivery of L’Astrolabe, collaboration with Aker Arctic was highly constructive, and sharing Aker Arctic’s experience in the design and construction of Arctic vessels proved particularly valuable. Together, the two companies identified the best technical solutions to achieve the required performance and meet the tight delivery schedule.

“Our interest in Antarctic science goes far beyond commercial considerations,” says Lönnberg. “As climate and ice conditions continue to change, staying closely connected with the latest polar research is essential. It is the only way we can continue designing vessels that are truly suited to the challenges of future Antarctic missions.”

| Technical details |

|---|

Length: 72 metres |

Beam: 16 metres |

Draught: 5.2 metres |

Deadweight: 1,600 tonnes |

Open-water speed: 14 knots |

Propulsion power: 6.4 MW |

Icebreaking: 80 cm level ice |

Ice class: BV Icebreaker 5 |

Complement: 60 people |

Text by Catarina Stewen