Canadian Polar Icebreaker project advances

Since 2021, Aker Arctic has been engaged in updating and improving the design of the Polar Icebreaker for the Canadian Coast Guard, which will be constructed at Seaspan’s Vancouver Shipyards. The final phases of the functional design were completed last year, concurrently with the initial steps of the production design.

The construction engineering of a vessel project consists of two main phases: functional design and production design. The latter aims to finalise the ship’s design and develop workshop specifications for the building phase to enable vessel construction to start. The production design of the Canadian Polar Icebreaker is expected to be concluded by the end of 2025 or the beginning of 2026.

Expertise in ice

The Polar Icebreaker project for the Canadian Coast Guard resumed in 2021 with a comprehensive design update, integrating the latest technological advancements and optimising the design for construction. Aker Arctic has been part of the design team since the project began in 2012.

The company’s responsibilities have encompassed the icebreaker’s hull form, ice strengthening of the hull structure, performance, stability, and winterization. In addition, Aker Arctic has provided ongoing support for Seaspan’s design team.

Ice-strengthened propeller delivery

As part of the design update, the hull form was further refined, and different propulsion options were evaluated. The performance of the selected hybrid propulsion configuration with two azimuthing propulsion units flanking a centre shaftline was verified with model tests in both ice and open water.

Aker Arctic has designed and delivers the ice-strengthened Polar Class 2-rated stainless steel propeller, which has a diameter of six metres, for the icebreaker’s 12-megawatt centre shaftline. Delivery of the propeller to the shipyard in Vancouver is scheduled for 2025.

Design propeller model tests verify the design

In spring 2024, design propeller model tests were conducted to verify that the hull and propulsion unit configuration design produces the required thrust to meet the open water and icebreaking performance criteria, and that the vessel is capable of performing its intended operations in the challenging conditions of the Canadian Arctic.

“Once we received the final propulsion measurements, we were able to confirm that the hull form was correctly designed. These tests are crucial as they finalise the hull design and complete one of the fundaments of the design project,” Project Manager Jukka-Pekka Sallinen explains.

Auxiliary systems enhance performance

Several auxiliary systems have been designed to enhance the vessel’s performance, including a roll stabilisation system to reduce wave-induced motion, and an air bubbling system to minimise friction between the hull and the ice. Aker Arctic has also been responsible for preparing the design documentation and ensuring that the systems function correctly.

“The performance of these systems will be confirmed in the various commissioning tests during the building phase and also in sea trials,” says Sallinen.

3D modelling review in progress

The 3D modelling process for production is currently underway. Aker Arctic is reviewing all design elements under its responsibility to ensure accurate representation in the model. The finalised 3D model is expected to be completed by late 2025.

According to Sallinen, the most intensive phase of Aker Arctic’s design work is now completed. “When construction begins, we will continue supporting the shipyard throughout the building process.”

Technical authority support role

Aker Arctic has also assumed a technical authority support role to ensure adherence to high-quality design principles and compliance with standards and regulations to support the shipyard’s Technical Authority team. This has included thoroughly reviewing design documents to confirm that requirements for operation in extreme cold and ice-covered waters are properly incorporated.

“As the functional design phase comes to an end, a large part of our work in this role is now also complete,” says Naval Architecture Team Leader Jillian Adams.

Future impact of the Polar Icebreaker

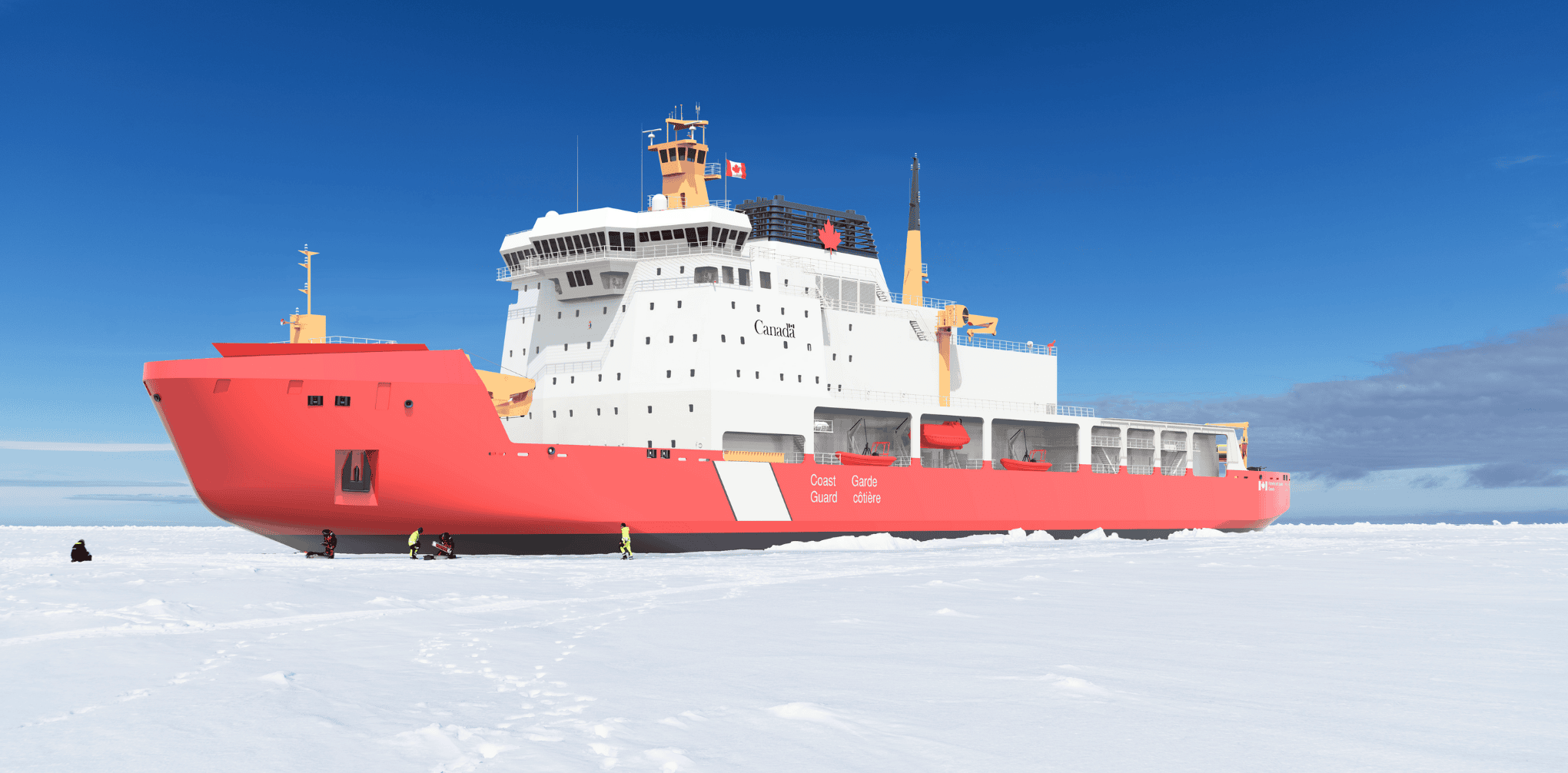

The new Polar Icebreaker will replace the Canadian Coast Guard Ship Louis S. St-Laurent, making it the most powerful conventional icebreaker in Canada and among the most capable in the world.

The vessel will ensure the Canadian Coast Guard maintains a year-round presence in Canada’s North, supporting Indigenous Peoples and northern communities, safeguarding Arctic sovereignty, facilitating high Arctic scientific research, including climate change studies, and responding to major maritime emergencies. The Polar Icebreaker is expected to be delivered by 2030.

Text by Catarina Stewen