The world’s first oblique icebreaker raised agility to a new level

Our 20th anniversary article series continues with the story of the pioneering oblique icebreaker Baltika, featuring an asymmetrical hull. She can break wide channels in ice using her port side and recover oil spills with her starboard side.

The oblique icebreaker concept emerged from an internal innovation contest in the mid-1990s. At that time, new oil terminals were planned for the Gulf of Finland, and it was anticipated that Aframax-sized tankers with a beam of more than 40 metres would become the standard for oil transport in the region. Due to their wide beam, escorting such tankers would require at least two traditional icebreakers, unless a new solution could be found.

Winner of the innovation contest

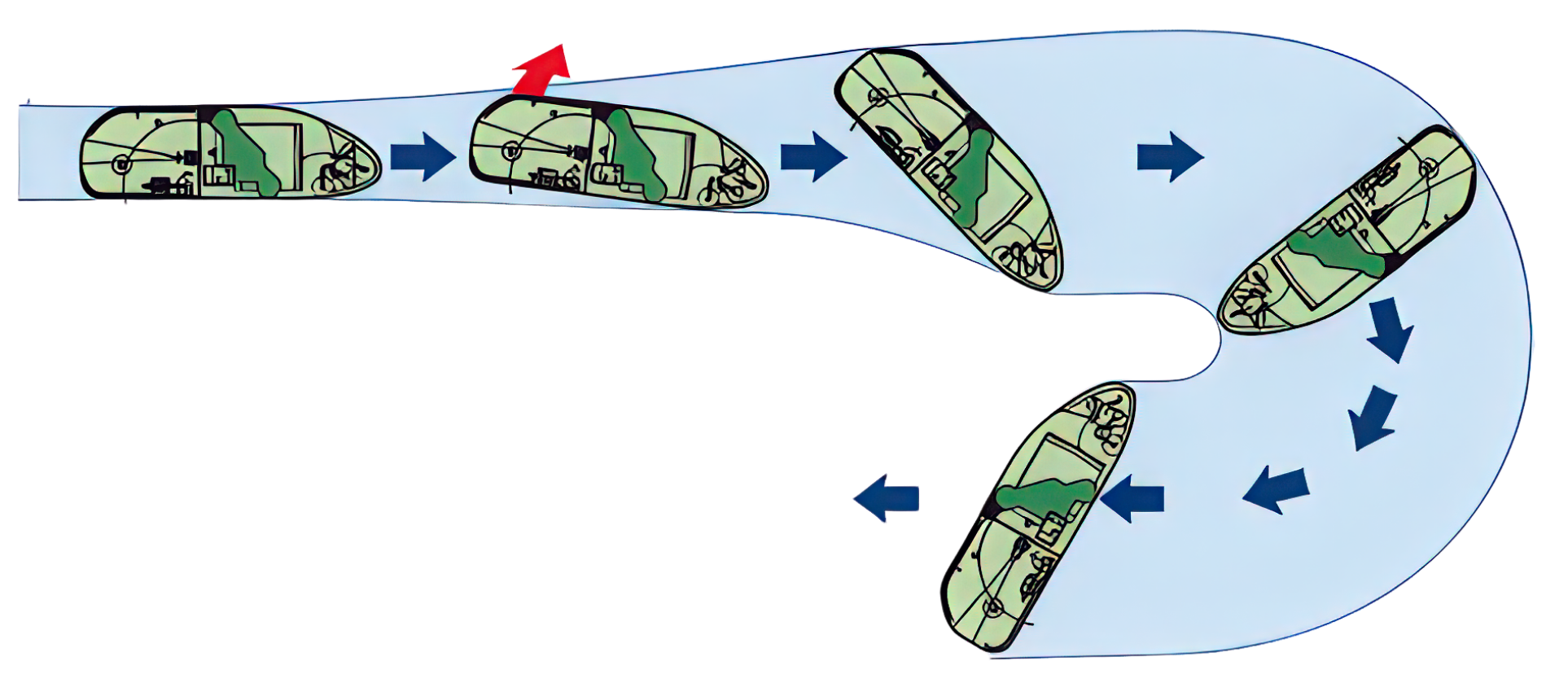

The oblique icebreaker concept won the competition, and a patent application was filed in 1997. The revolutionary idea was that a relatively small icebreaker, with an asymmetrical hull, could break ice sideways to create a wide channel for larger ships. With this cost-efficient solution, only one icebreaker would be required for assisting bigger ships.

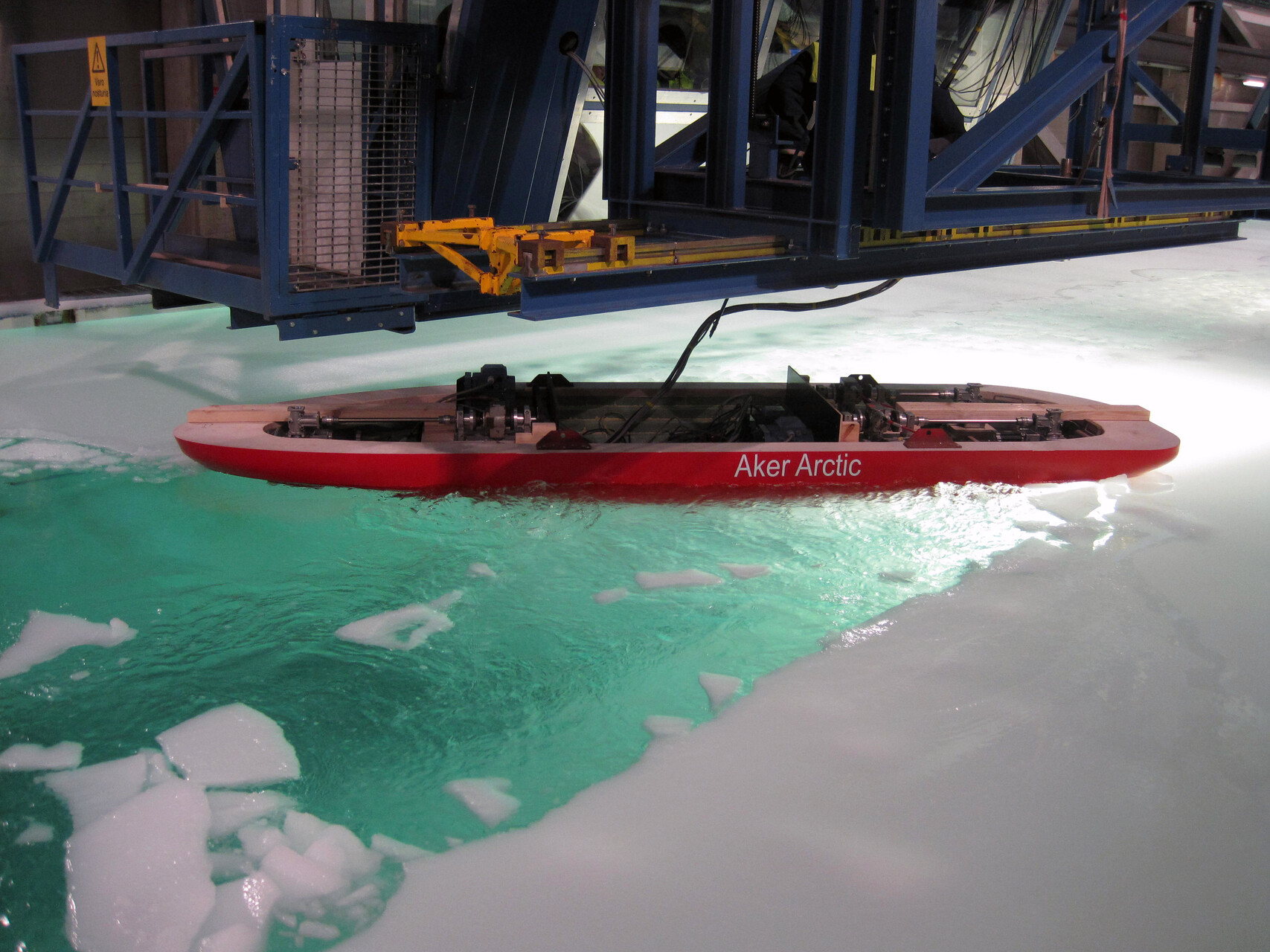

Many series of model test were performed during the development process to ensure that the novel concept could create a 16-metre-wide channel in normal operations and a 40-metre-wide channel in oblique mode. As the vessel was planned for all conditions in the Gulf of Finland, testing also included breaking 1.2 metres of level ice.

A few years later, the concept was further developed to include oil spill response functions. The innovative sideways movement could be harnessed to collect oil efficiently in the event of a marine casualty.

From concept to construction

For years, Aker Arctic promoted the oblique icebreaker concept, firmly convinced of its innovative potential. When the first such vessel was ordered in 2011, the original hull design was revised for improved producibility. For example, the midship section was straightened and the propulsion layout was optimised without compromising the vessel’s oblique functionality.

Chief Designer Mika Hovilainen recalls being a ship design trainee at the Helsinki Shipyard in early 2000, when he first encountered the oblique icebreaker concept.

“At that time, the hull had no straight lines, as it was designed purely from an icebreaking perspective,” he says. “Later, Baltika taught me hands-on why ships are usually symmetrical.”

Overcoming open-water challenges

Hovilainen and his team of ship designers recognised early that the asymmetrical hull could pose rolling challenges in heavy seas. As a precaution, they agreed with the shipyard to carry out seakeeping model tests before proceeding with the shipbuilding contract.

Initial results were discouraging. During standard operations in head seas, the vessel’s roll period resonated with the wave period, amplifying the rolling motions. This hydrodynamic issue had to be resolved before contracting could move forward.

The ship design team, in collaboration with the company’s hydrodynamic experts, adopted a combination of a box-shaped roll-damping tank and a roll-damping hull appendage, convinced that this would solve the excessive motions. Since traditional bilge keels are susceptible to damage in heavy ice conditions, a robust design suitable for an icebreaker was developed and installed only on the non-icebreaking side of the hull.

Subsequent seakeeping tests showed a 70% reduction in the rolling motion, a breakthrough that enabled the construction of the multipurpose emergency and rescue vessel to begin in autumn 2011.

“Given the novelty of the concept, we decided to conduct more ice model tests than usual to assess propulsion, steering, resistance, and overall ice performance,” Hovilainen notes.

Delivery of a groundbreaking vessel

Baltika, delivered in early 2014, represented a milestone in icebreaking and oil spill response technology. Her asymmetrical hull is paired with three Steerprop pulling azimuthing propulsion units, two at the stern and one at the bow, allowing her to operate flexibly ahead, astern, and sideways. She could even turn on the spot while in ice, an unprecedented feature at the time.

Baltika’s asymmetrical hull features sloping icebreaking geometry on her port side, which enables her to open a 50-metre-wide channel in ice when operating obliquely, with the port stern quarter acting as the bow. The starboard side is equipped for oil recovery, which can be conducted in seas with up to two metres of significant wave height. The sideways motion allows oil to be collected along the entire length of the vessel into a recovery chamber containing a brush-conveyor-belt-type skimmer unit.

Designed for the Baltic – proven in the Arctic

Baltika was designed to operate in Baltic Sea conditions. However, after delivery, she was taken for ice trials to the Gulf of Ob in the Arctic, where ice conditions are more severe. During the voyage, she faced rough seas and winds of up to 30 m/s off the coast of Norway. Her performance in these conditions impressed the owner and confirmed her suitability for harsh environments.

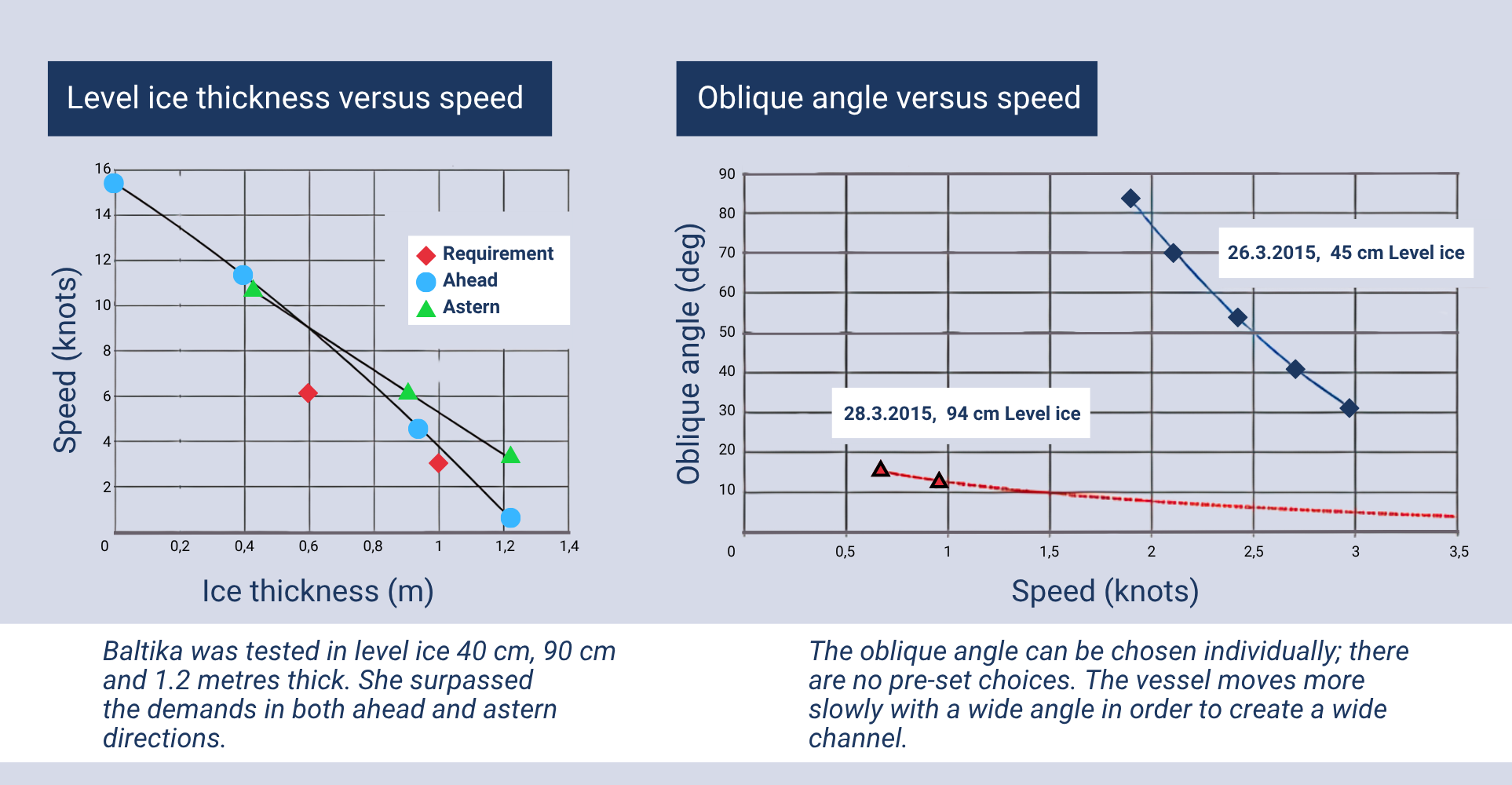

An Aker Arctic team — Mika Hovilainen, Teemu Heinonen, Esko Huttunen, and Tuomas Romu — boarded Baltika in Murmansk. After rounding the northern tip of Novaya Zemlya, the vessel headed to the Gulf of Ob. The testing programme included performance trials in three ice thicknesses (40, 90, and 120 cm), conducted in ahead, astern, and oblique modes. Various operational tests were also carried out to evaluate her manoeuvrability and operational capabilities.

An automatic measurement system was set up to record ice loads on the ship’s hull throughout the three-week voyage.

Baltika surpassed all expectations. Despite ice strength properties being twice the specified value, she exceeded performance targets in both forward and reverse operations.

Real-life success in oblique mode

The oblique mode, previously untested in real conditions, proved successful and confirmed that the vessel met all design requirements. When moving sideways, the compact icebreaker could create a wide channel in ice. A dynamic positioning system, coupled with a custom joystick, was essential for controlled oblique navigation.

Various angles of attack were tested in different ice thicknesses. The conclusion was that smaller angles of attack produced narrower channels at higher speeds, while wider angles created broader channels at slower speeds. Baltika also demonstrated excellent manoeuvrability and performance in rubble clearing and ice management tasks.

The trials confirmed that Baltika could perform the same operations as conventional icebreakers using only half the propulsion power, as well as perform manoeuvres previously unthinkable for icebreakers.

“The concept proved that we had succeeded in reaching a new level of efficiency in icebreaking,” Hovilainen remarks. “Baltika was also the first icebreaker with an azimuthing propulsion unit in the bow, a groundbreaking innovation that we have since applied to several projects to enhance agility and manoeuvrability.”

| Technical details |

|---|

Length: 76.4 metres |

Beam: 20.5 metres |

Draught: 6.3 metres |

Power: Diesel-electric power plant with three Wärtsilä 9L26 generating sets, total output 9 MW |

Propulsion: Three 2.5 MW Steerprop SP60PULL azimuth thrusters, two in the stern, one in the bow |

DP system: Dynamic positioning system by Navis Engineering |

Oil recovery: Built-in system |

Classification: RMRS Icebreaker6 |

Data from Baltika used in ice-load research

Baltika, an exceptional and innovative vessel, has served as a valuable research platform over the past decade. In 2014, she was equipped with a strain-gauge-based measurement system to monitor ice loads on her oblique hull form. Data collection continued for five consecutive years, and the results have been used in theses and have contributed to the development of the Ice Load Monitoring System (ILMS).

Naval Architecture Team Leader Jillian Adams was the first to complete a master’s thesis analysing the data collected from Baltika. She further developed an inverse engineering method, originally implemented by Teemu Ikonen for his master’s thesis in 2013, enabling the analysis of full-scale strain measurements taken onboard Baltika.

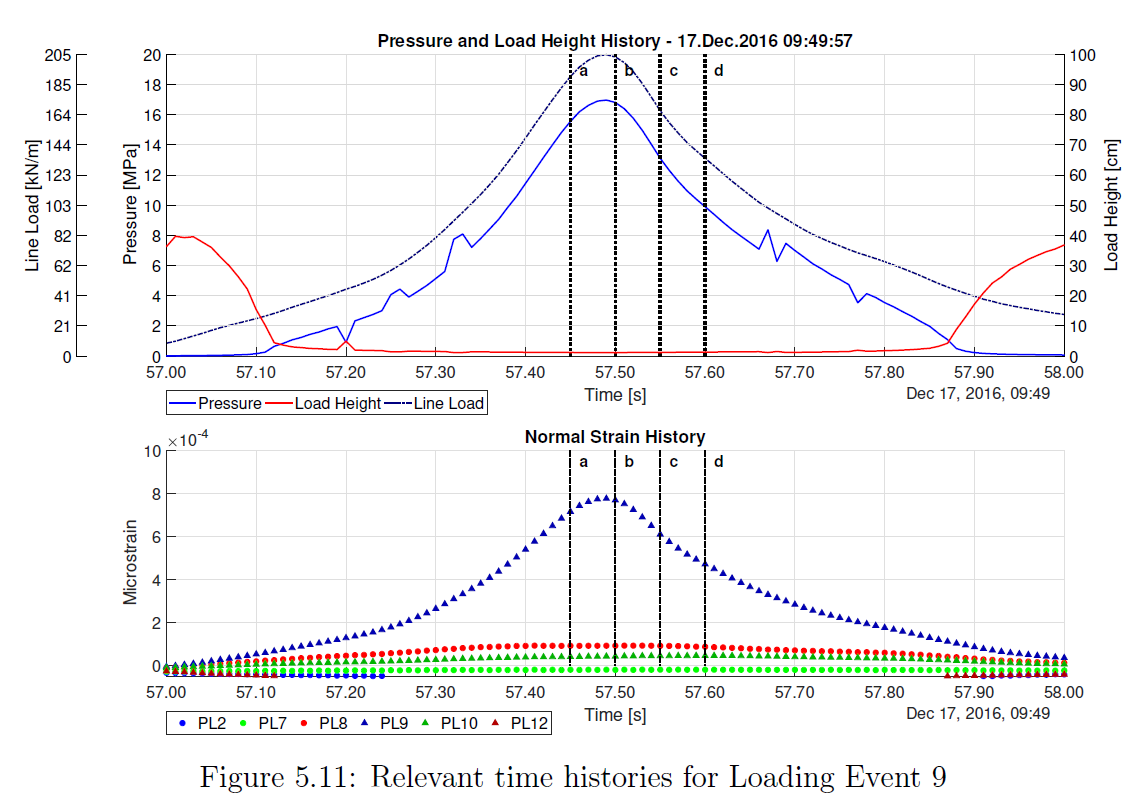

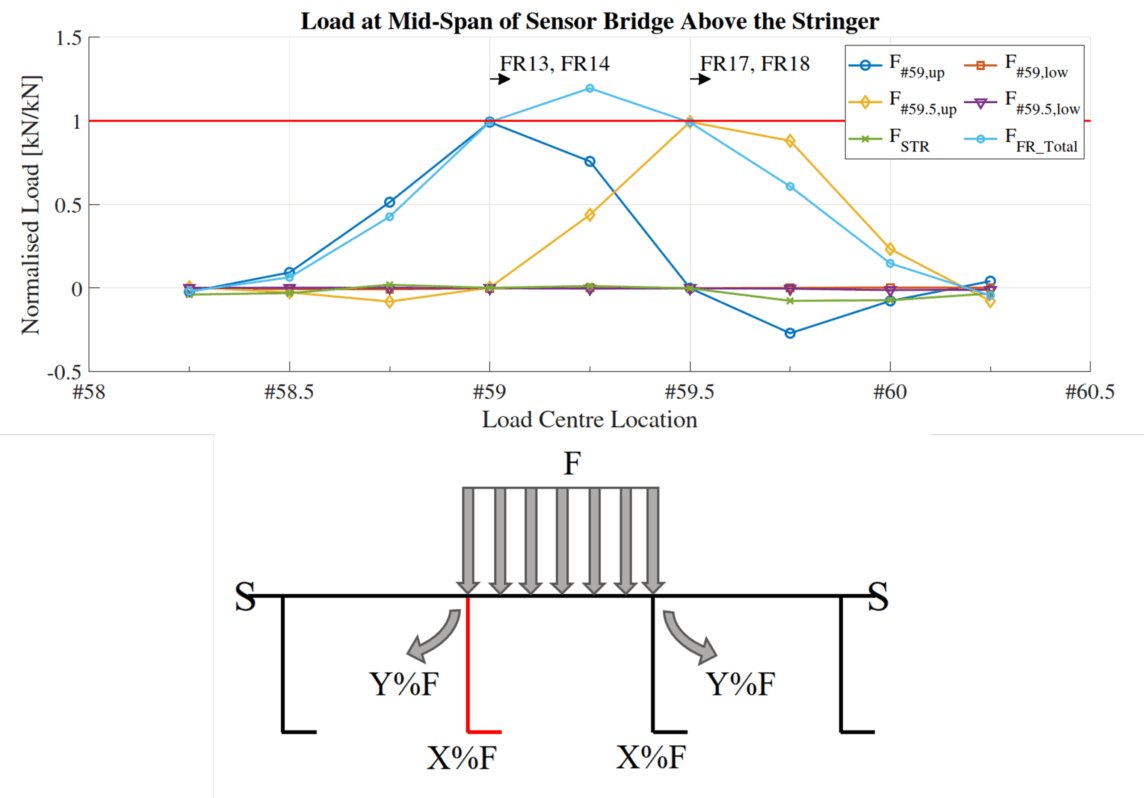

In her research, Adams applied two discretisation patterns to estimate the pressure and load patch height induced by impact events between the ship and the surrounding Arctic sea ice. Using finite element analysis, she created an influence coefficient matrix describing the strain response of the hull structures to ice loads.

This inverse method was applied to strain measurements from 250 impact events to analyse maximum ice-induced loads. From these, 98 events were selected for detailed analysis of the full impact event.

Narrow ice-load height validated

Adams’ main finding was that the ice-induced load was line-like, as suggested by previous research, and was concentrated within a height of one to three centimetres.

“It validated that the load patch height is actually very narrow, as opposed to what is commonly assumed,” Adams explains.

During her calculations, Adams observed that the total load on the frame was significantly less than expected. This finding led to another thesis at Aker Arctic, completed by Tomás Sanches, who investigated whether a peak pressure component exists with a lower-pressure area behind it. His conclusion, however, was that only a line load exists, although results can vary depending on which side of the frame is instrumented.

“Therefore, both sides of a vessel’s frame have to be instrumented with sensors,” Adams says.

Results fed into ILMS development

Since Adams’ and Sanches’ theses, additional research projects have been conducted based on ice-load monitoring on other vessels, such as RRS Sir David Attenborough, and most recently Le Commandant Charcot. The results from all these research projects have contributed to the development of the Aker Arctic Ice Load Monitoring System.

“The measurements on Baltika provided us with a five-year data set, but equally important was the practical experience: where to place the sensors, how to conduct the measurements, how to process the data, and interpret the results,” Adams says.

Structural Engineer Ville Valtonen adds that the long-term development of ice-load monitoring has greatly enhanced Aker Arctic’s understanding of what the sensors are measuring and why – knowledge that is crucial when interpreting results. He is currently researching how to optimise the amount of steel in a ship’s primary structures to avoid excessively heavy hulls, as part of his PhD studies.

Continuous R&D

According to Adams and Valtonen, ice as an engineering material is unpredictable as it is naturally near its melting point. Therefore, research on how ships interact with ice is continuously ongoing at Aker Arctic, as the topic is far from mature.

“As a leader in our field, our aim is to keep improving and deepening our expertise to stay ahead,” Valtonen says.

In addition to Valtonen’s PhD studies, there are currently three thesis projects underway at Aker Arctic.

Text: Catarina Stewen