Three remarkable icebreaker contracts

During the past three months, three polar icebreakers have been contracted for construction around the world. They all feature Aker Arctic’s patented Hybrid DAS™ propulsion configuration.

On 19 December 2024, the German research institute Alfred Wegener Institute contracted thyssenkrupp Marine Systems to build the new flagship for German climate research, Polarstern II. The 160-metre state-of-the-art multidisciplinary research icebreaker will feature extensive scientific facilities and accommodation for 60 to 90 scientists and 50 crew.

On 7 March 2025, the Government of Canada awarded Seaspan’s Vancouver Shipyards Co. Ltd. (VSY) the construction contract for the first new heavy polar icebreaker for the Canadian Coast Guard under the National Shipbuilding Strategy. The 158-metre vessel will become one of the most advanced and capable icebreakers in the world.

On 8 March 2025, Chantier Davie Canada Inc. (CDCI) was awarded the construction of the second heavy polar icebreaker for the Canadian Coast Guard. The 139-metre vessel will be built jointly with Helsinki Shipyard in Finland.

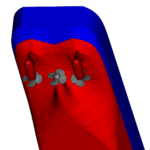

What is common with these three projects, apart from their high ice class, Polar Class (PC) 2, is that they all feature Aker Arctic’s patented Hybrid DAS™ propulsion layout: two azimuthing propulsion units flanking a fixed shaftline in the middle. Dubbed “the best of both worlds”, it combines the exceptional maneuverability of azimuthing propulsion with the design flexibility and robustness of the fixed shaftline. Gaining popularity in recent years, the twin-azimuth hybrid configuration has largely replaced the classic triple-shaft configuration prevalent in polar icebreakers since the late 1800s.

Over the years, Aker Arctic has developed and tested various configurations in model scale to determine the optimal hull geometry, propulsion power split, and position of the azimuthing propulsion units relative to the shaftline in the middle.

Through numerous design studies and ice model tests in our own ice laboratory, we have also identified certain challenges and potential issues that must be addressed to ensure that the propulsion system functions as intended in both open water and ice. Two of the three icebreakers now contracted feature a hull form developed by Aker Arctic and tested in our ice laboratory in Finland.

Aker Arctic is proud to contribute to icebreaker projects, bringing world-class Arctic vessel design and ice testing expertise to these historic projects. Our proven technologies and world-class capabilities provide shipowners with an icebreaker built to operate in the harshest conditions. Through our partnership, we strengthen Canadian and German capabilities and apply new technologies to the latest icebreaker innovations.

Continue reading the related articles: