Le Commandant Charcot – from dream to icebreaking reality

What began as a dream – to take passengers safely to the North Pole – has become a remarkable reality. Le Commandant Charcot is not just a ship, but a symbol of vision, collaboration, and technical mastery. She is the first of her kind: a Polar Class 2 cruise ship that blends the strength of an icebreaker with the comfort of a luxury liner, charting new courses in some of the most remote regions on Earth.

In 2015, Ponant dared to dream of something no one had attempted before: a cruise ship capable of reaching the North Pole on a regular schedule. When they brought the idea to Aker Arctic, the first reaction was hesitation, which soon turned into excitement. Always eager to embrace challenges related to ice navigation, we began work to make Ponant’s ambition a reality.

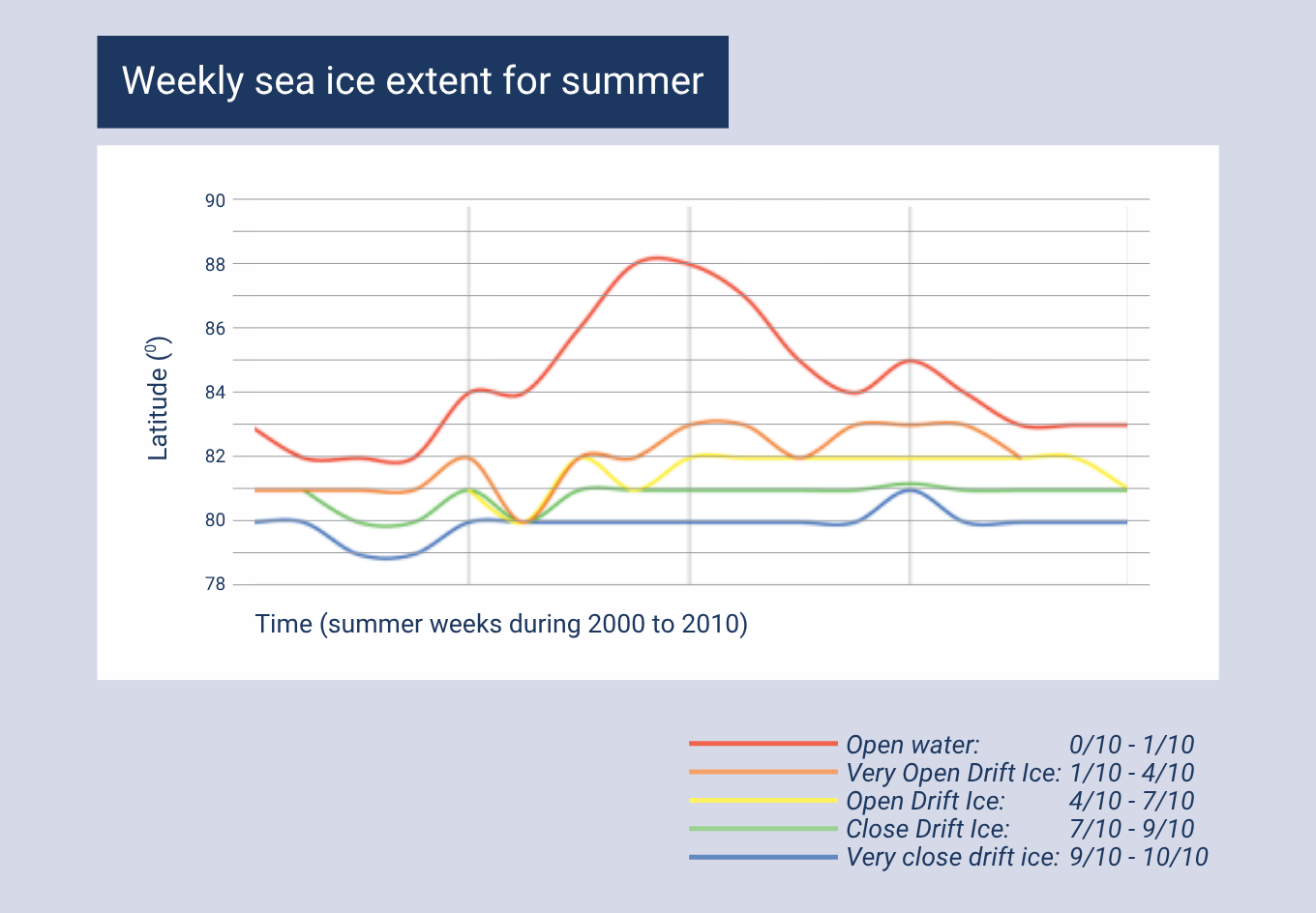

The first step was a comprehensive ice study to assess environmental conditions and identify the requirements for a vessel capable of reaching the North Pole. This included evaluating questions such as: How long would it take to sail from Svalbard or Iceland? Could a reliable cruise schedule be built around such voyages? And, most importantly, what kind of ship could face the harsh Arctic conditions?

The first Polar Class 2 ship

To find the answers, Aker Arctic collected and analysed a decade of ice data (2000 to 2010). The study concluded that even summer operations would require a Polar Class (PC) 2 vessel.

That result set history in motion. Le Commandant Charcot would become the first PC 2-class vessel ever built, designed to carry passengers in comfort to the Arctic during the northern summer and to Antarctica during the southern summer. To date, she remains the only ship delivered to the second-highest Polar Class rating, with Canada’s upcoming polar icebreakers – also Aker Arctic designs – set to follow.

The path from concept to construction was one of constant collaboration. The initial outline of the ship was prepared together with Ponant and Stirling Design International. Aker Arctic was then responsible for everything from the main deck downwards, including the machinery and design of the hull to meet the stringent performance requirements, while Stirling Design envisioned the upper decks and interiors. Ponant guided the overall development to ensure the concept aligned with their operational vision.

Technical design work in stages

By 2017, Aker Arctic had advanced to the technical design work. Ponant, already engaged with the Norwegian shipyard Vard on other projects, shortlisted them for the construction of Le Commandant Charcot. Unlike typical projects, where the full design is handed over for tender, this one unfolded in stages. Step by step, Aker Arctic developed technical solutions, which were then integrated by the parties into contractual documentation.

“It required more discussions and iterations, but the end result was extraordinary,” Chief Designer Maximilian Vocke recalls.

According to Mathieu Petiteau, Ponant’s Newbuilding Director and Project Manager of Le Commandant Charcot, their expectations in terms of ice capabilities, comfort at sea and in the ice, safety, and sustainability were so high that the shipyard called her “the Spaceship”.

“The results are outstanding from many points of view,” he says.

Collaboration with the shipyard during construction

The shipbuilding contract was signed in 2018. While the shipyard oversaw the basic design, Aker Arctic ensured that all ice-related features met the demanding nature of Arctic and Antarctic operations, including hull design, steel classification drawings, model tests, and propulsion systems.

“At an early stage, Vard invited us to participate in all aspects we saw as relevant for a successful vessel project,” Vocke says. “As this was an entirely new class of ship, we also held numerous meetings with the classification society to ensure compliance with the rule requirements.”

Due to the vessel’s high ice class, proper hull and structural design was critical. Responsibilities were divided: Aker Arctic managed the class drawings for the ship’s hull and performed FEM calculations for the entire ship, while Vard handled the structures in the deckhouse. Aker Arctic also designed ice-critical systems such as the cooling arrangements, the propulsion system, sea chests, and winterisation guidelines.

“For example, in ice-covered waters, preventing ice rubble from entering the cooling system is vital, as this could end up in reduced engine power and bring the entire ship to a halt,” Vocke explains.

Hull construction took place at Vard Braila in Romania. The original plan was to first tow the hull to Chantiers de l’Atlantique in France for the installation of the Azipod® propulsion units, and then to Vard’s Norwegian yard for outfitting and finalisation. However, pandemic disruptions required an additional transfer between Norway and France.

Ice trials validated the design

By the summer of 2021, Le Commandant Charcot was ready for trials in both open water and ice. These verified that her performance met the specifications and matched the results of earlier ice model tests performed at Aker Arctic’s ice laboratory prior to construction.

A joint crew of Ponant, Vard, flag authorities, and the Aker Arctic ice trials team – including Teemu Heinonen, Jukka-Pekka Sallinen, and Maximilian Vocke – sailed north from Norway, testing the vessel in thick ice fields near Svalbard and Greenland.

The trials were as dramatic as they were decisive. Le Commandant Charcot pushed steadily through 2.5 metres of ice, sailed stern-first in nearly 2 metres of level ice, and penetrated an 18-metre ridge. Even when propulsion power was reduced to half to simulate a damage scenario, she pressed forward with a speed of 2 knots ahead in 1.6-metre-thick ice to demonstrate sufficient capabilities for a safe return to port.

“The ridge penetration was an exciting moment after a full day of preparation,” Vocke says. “Teemu Heinonen guided the captain in charge on how to control the ship and which way to turn the thrusters, while everyone else on the bridge listened attentively.”

For those on board, this was the moment the dream became reality. After the ridge test, Petiteau, who supervised the vessel’s concept development, design, and construction, delivered a public address in which he thanked Aker Arctic for designing a ship capable of overcoming such an obstacle, receiving a warm applause from all on board.

The world’s most capable icebreaking ship

Le Commandant Charcot is unlike any ship afloat. She features a modern icebreaking hull form that combines smooth icebreaking performance ahead in thick multi-year ice, with astern capabilities in severe ice conditions using the double-acting ship principle (Aker Arctic DASTM). While she mostly operates in ahead mode, she can switch to astern mode to avoid becoming beset in ice – a genuine risk in the compressive Arctic pack ice.

Twin azimuthing propulsors and a hybrid-electric LNG power plant provide unique efficiency and manoeuvrability. The combination of state-of-the-art technology with the most powerful ice-strengthened propulsors of the time, paved the way forward for sustainable polar icebreaking, while also making it accessible to passengers as a cruise ship. She complies with IMO and ECA regulations and fulfils the “clean ship” requirement with advanced wastewater treatment, energy optimisation, a heat recovery system, and zero emissions in electric hybrid mode.

The vessel’s performance is comparable to that of the most powerful polar icebreakers in the world, but thanks to modern solutions, she goes a step beyond, with greater icebreaking efficiency and fuel economy.

“She is the world’s most capable diesel-electric icebreaker, blending luxury and icebreaking strength,” Vocke highlights.

Quiet strength in ice

As a luxury vessel, passenger comfort was a central design goal. Vocke explains that Aker Arctic’s design team made considerable efforts to ensure broken ice flows away from the vessel, minimising hull-ice interaction and reducing noise.

“Breaking 2.5-metre-thick ice creates massive ice blocks the size of trucks. Without proper flow management, these would bounce against the steel hull, producing unbearable noise and vibrations,” he says.

Solid experience and extensive model testing were key to achieving this balance.

“Having designed numerous ship hulls, we know what works and what doesn’t,” Vocke adds.

Safety at the edge of the world

Sailing into the planet’s most inaccessible places demands more than strength – it requires foresight. Ponant placed passenger safety at the heart of the project.

They developed their own customized polar survival equipment and a deployable polar survival camp that can sustain 460 people for up to five days on ice, land, or sea in extreme conditions. The crews regularly practise assembling the camp, and passengers are shown safety and survival demonstrations during voyages.

A testament to Ponant’s commitment to safety was the full-scale dry-run expedition they organised to the North Pole before the vessel’s maiden cruise to Antarctica. The crew and invited experts practised survival drills, tested lifesaving systems and survival equipment, and learned how to operate the ship in polar conditions before welcoming passengers on board.

Breaking boundaries

Since entering service four years ago, Le Commandant Charcot has redefined polar cruising. She has averaged 200 days per year in ice, exploring the highest latitudes in both the Northern and Southern Hemispheres. The vessel has reached the North Pole yearly and transited through the Northwest Passage to study the region’s complex and challenging ice conditions.

In September 2024, she made history by becoming the first vessel to reach the legendary North Pole of Inaccessibility during a transpolar transit from Alaska to Svalbard. Having also reached the magnetic and geographical North Poles on the same voyage, Le Commandant Charcot became the first vessel to cross all three North Poles in a single journey.

The lead captain for the historic cruise, Captain Etienne Garcia, says:

“Le Commandant Charcot is the only cruise ship in the world with a PC 2 ice class, enabling her to reach places no other vessel can. She is uniquely designed for observation, with panoramic windows that allow passengers to enjoy the breathtaking scenery from the warmth of the interior. No other ship compares.”

In 2025, Le Commandant Charcot carried out another transit across the North Pole, this time in the opposite direction, from Svalbard to Alaska.

Ice load monitoring validates operational insights

To support safe operations on the extraordinary routes the ship sails, Aker Arctic has installed its ice load monitoring system, ARC ILMS, on the vessel. Strain-gauge sensors mounted on the internal hull structure track hull responses to ice loads in real time, both when operating ahead and astern.

Analyses of the data show that even in the most demanding areas – such as eastern Greenland in spring, the Northwest Passage, and in multiyear ice in the extreme north of Canada – the vessel typically operates at just 50-60% of her full capacity, well within safety margins. According to Captain Garcia, this is reassuring, confirming that they are operating the vessel correctly.

A vision realised

Reflecting on the project, Chief Designer Vocke describes it as a career highlight.

“It has been a once-in-a-lifetime project to create something so challenging, with such a rewarding result,” he says. “Ponant is truly visionary – willing to break boundaries and set new standards. Together, we created something no one else had attempted.”

When Le Commandant Charcot called at the Port of Helsinki in November 2024, the entire Aker Arctic team was invited for a guided tour and lunch on board. One of the specialities of the luxury ship is its exceptional culinary offerings.

“It was a rare opportunity for many at Aker Arctic to see firsthand the remarkable outcome of our collaboration,” Vocke adds.

With Le Commandant Charcot’s success, Aker Arctic further proves its capabilities in conquering the world’s most demanding ice conditions. With experience that spans from light icebreaking to the heaviest icebreaking in the world, Aker Arctic’s portfolio demonstrates unparalleled expertise in the realm of ice-going and icebreaking ships.

“Our mission now is to design even better and more efficient vessels. We look forward to new projects where we can challenge our expertise and realise our customers’ dreams. Even the most impossible journeys can become reality,” Vocke concludes.

Text by Catarina Stewen