Ice navigators typically have no qualitative indication of how close to the structural limits they are operating their assets. Mariners experienced with ice operations develop an intuitive feel for this over time. However, operators new to working in ice or that that only occasionally operate in ice have not had an opportunity to develop this intuition. Therefore, mariners must necessarily operate conservatively in order not to risk damaging their vessels.

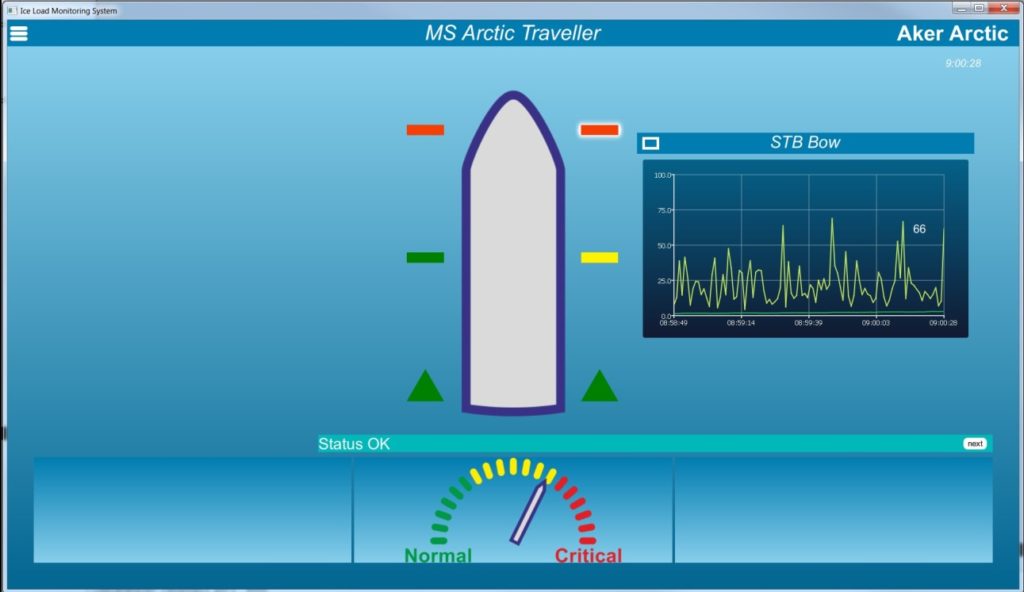

ILMS improves the operational safety, accountability, and efficiency of shipping operations. Improved safety is achieved through an on-bridge interface, which provides real-time feedback of the current operating status. ILMS uses a unique prediction tool developed by Aker Arctic, to forecast risk when the ice loads reach critical levels, allowing ice navigators to take preventative actions. Integrated online monitoring and logging allow shipowners to monitor their assets and can be used to justify suspending operations if conditions become unsafe. Data retrieved from the ILMS can be used to conduct post-event and seasonal analysis, allowing clients to better understand their operations and refine operational procedures improving efficiency.

Aker Arctic’s in-depth knowledge of ice loads and hull structures is central to the delivery and installation of the ILMS. The ILMS relies on a network of sensors that measure the hull stress, thereby inferring the ice loads. Although ILMS can be installed over top of any third-party sensors, the placement of the sensors is critical to ensuring that peak loads are captured. The ILMS is a complete EPCI solution consists of:

- Feasibility Study – Assessment of number sensors, sensor manufacture, and rough placements

- System Engineering – Finite element modeling, detailed sensor placement, and system configuration

- Installation – Procurement and mounting of sensors, running cables, and installation of bridge display

- Monitoring – Data logging, seasonal and user specific analysis.

Currently we are also developing propulsion line monitoring, which will be integrated into our ILMS. Ice load monitoring also has potential application for autonomous vessels to monitor ice condition during operations in ice.

You can find some printed material here and in the articles from our Arctic Passion News:

ILMS development

Ice load monitoring and prediction helps in decision making.

ILMS is installed

The self-propelled detachable icebreaking bow was developed to improve icebreaking capacity on Lake Saimaa.

ILMS commissioned remotely

Sensors installed on the hull and the shaft lines send information to a central computer for real time processing.